Low-diffuse reflection paints are not just paints, but are technologies that have the potential to bring innovation in a variety of fields. Functionality and durability are improved, and the range of applications of low-diffuse reflective paints is expected to continue to expand.

Dramatically improve the accuracy of LiDAR sensors! State-of-the-art technology for low-diffuse reflective paints

Product literature is available.

LiDAR Sensors and Low Diffuse Reflective Paints: Innovative Encounters Open Up Possibilities

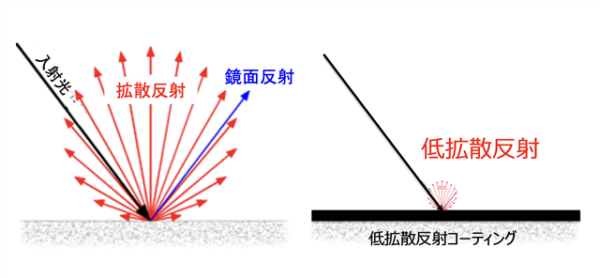

In recent years, with the development of autonomous driving and robotics technology, the importance of LiDAR sensors has increased. However, conventional LiDAR sensors are heavily affected by the reflective characteristics of object surfaces, and have problems such as reduced accuracy and false positives. The key to solving such problems is “low-diffuse reflection paint” that makes full use of innovative technology. Unlike conventional paints, it is a revolutionary paint that has the function of diffusing light in various directions rather than completely blocking it.

Low-diffuse reflection image

With this feature, the LiDAR sensor can achieve the following effects:

Improved accuracy: Equalizes the reflected light from the surface of the object, greatly reducing false positives in LiDAR sensors.

Stabilization of distance measurement: It is not easily affected by the unevenness of the object surface or the material, and stable distance measurement is realized.

Handling adverse environments: Stable performance even in rainy and foggy weather.

These effects are expected to dramatically improve the accuracy of LiDAR sensors and contribute to the further development of autonomous driving and robot technology.

Typical applications that require a function to prevent optical reflections.

1. Anti-reflection protection of the inner surface of the camera hood and lens barrel

2. Prevention of stray light on perforated light-shielding plates of optical measuring instruments

3. Prevention of stray light with integrated monitor and light-emitting HUD

4. Interior surface of the car meter

These applications include flocked sheets with rough surfaces, black oxide coatings and anti-reflective coatings.

Versatile Applications of Low-Diffuse Reflective Paints: Expanding the Possibilities of LiDAR Sensors "Low-diffuse reflection paint supports sensor technology."

The application of low-diffuse reflective paint is for self-driving cars equipped with LiDAR sensors and

It is not limited to robots but is expanding in various fields.

– Architecture: LiDAR sensors and low diffuse reflection for inspection and inspection of structures such as buildings and bridges

The combination of paints allows for more accurate inspections.

– Manufacturing: Use of LiDAR sensors and low-diffuse reflective paints for product inspection and quality control

This allows for a more efficient production line.

– Agriculture: LiDAR sensors and low diffuse reflection to monitor crop growth and pest outbreaks

It can be efficiently monitored using paint.

– Medical: LiDAR sensor and low diffuse reflection for surgery, rehabilitation, etc.

The use of paints allows for more precise treatment and assistance.

In this way, low-diffuse reflective paints are attracting attention as a technology that greatly expands the possibilities of LiDAR sensors and brings innovation to various fields.

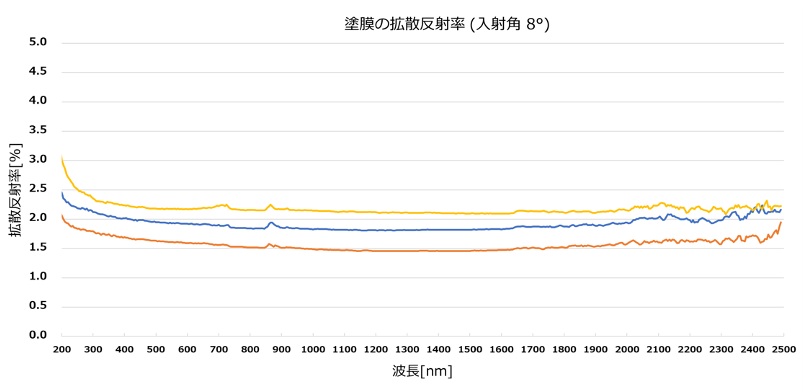

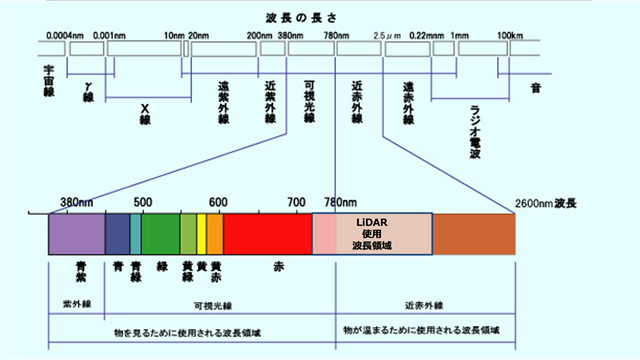

Wavelength 750 to 1500 nm in the near-infrared region used in LiDAR sensors

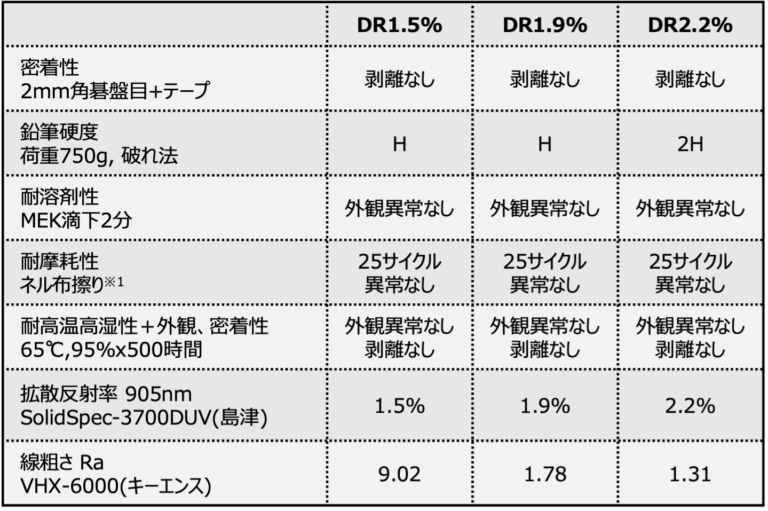

Low-Diffuse Reflection Coating Lineup

・Paint: TA64-DR NEORABASAN

・Paint: EC-GM62-DR ECO METALD

“Key Technologies”

(1) One coat or primer on a light shield of various plastic materials and metal materials Coating is possible by use.

(2) The diffuse reflectance does not change under a long-term high temperature and high humidity environment.

(3) Diffuse reflectance can be adjusted.

Remarks

DR : Diffuse Reflectance)

*1 : 500g/cm2, 1 inch, 25 cycles/min