MIRROR PAINT

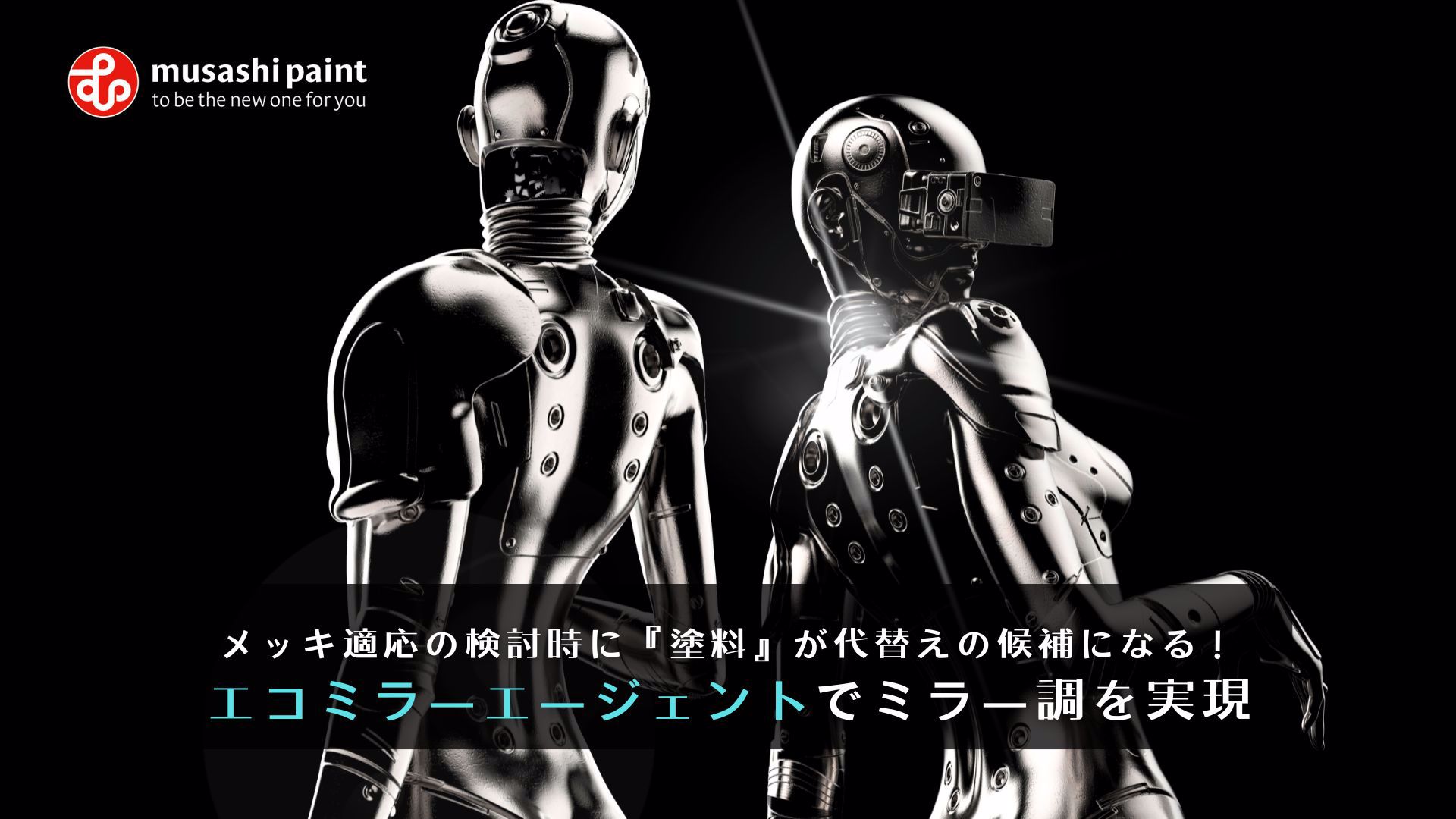

We, Musashi Paint proposes mirror-like paint to replace plating

As the name suggests, this paint is mirror-like and reflective.

When applied to the surface of the product, it creates a mirror-like shine and can be used to surface finish a variety of product

Mirror-like paints are characterized by their high brightness and decorative effect. It has a very high gloss and strongly reflects the surrounding light to create a mirror-like effect. The applied surface shines beautifully and plays a role in giving the product a sense of luxury and glamour. In addition, the combination of gloss and color can achieve various design and finish effects.

Is there a scene like this? Worries and issues in choosing plating ?

Our Strength

Plating creates a sense of luxury and glamour due to its luster, shine, and luxurious appearance. It gives the product a luxurious atmosphere and catches the eye of the beholder. However, from the viewpoint of environmental friendliness and sustainability, there are concerns that conventional plating methods are problematic.

Harmful chemicals and heavy metals are usually used in plating, and the manufacturing process and waste disposal are environmentally friendly. Therefore, it is important to explore sustainable manufacturing methods and materials. There is a need to develop alternative methods and materials to create products that can create a sense of luxury while minimizing the impact on the environment.

Worries of the person in charge of each department in manufacturing

● Designer Consistency and unity with the design

Consistency and unity with the design

When using plating, it is important to maintain a consistent and unified design. It is necessary to take into account the combination with different materials and colors, the harmony of plated and non-plated parts.

● Environmental Impact & Sustainability

The plating process uses chemicals, and there are concerns about the impact on the environment. It is necessary to consider the selection and processing method of plating in consideration of environmental friendliness and sustainability.

● Person in charge of design Constraints on Design Parts

The plating process can limit some designs.

For example, plating may be difficult for certain shapes and materials, and designers need to take these constraints into account when designing.

● Durability & Quality

Depending on the environment and conditions in which the product will be used, it is necessary to select the appropriate type and thickness of plating. You also have to consider the risk of the plating peeling off or discoloration.

New plating-like paint "Eco Mirror Agent"

Features of the “Eco Mirror Agent” that expresses the design of a mirror surface with conventional painting equipment

No special equipment required

There is no need for dedicated equipment or waste liquid treatment equipment. Since it is possible to achieve a mirror effect with conventional spray painting, the manufacturing process is more efficient.

Suitable for plastic substrates

It has made it possible to dry at a low temperature of 80°C, which was difficult in the past. As a result, it can be adapted to a wide range of plastic materials and used in a wide range of products.

Applicable to radio communication equipment

In general, metal plating does not transmit radio waves well and usually reflects radio waves. In particular, in the case of thick metal plating, the permeability of radio waves is low. However, this paint can achieve millimeter-wave radio wave band transmission, so it is suitable for use in radio wave communication equipment.

Weight reduction is achieved

When it comes to sports equipment, it is important to use lightweight materials. By reducing the weight, athletes can move more quickly and improve their performance. That’s why lightweight paints like Eco Mirror Agent are highly appreciated in the competitive world.

The need for products to replace plating

Plating contains toxic substances and heavy metals, and environmental pollution occurs in the process of its production.

In addition, peeling may cause deterioration of the product.

In light of these risks, in product development,

It is necessary to minimize the environmental impact and consider the choice of alternative materials.

Consideration for the environment

Harmful chemicals and heavy metals may be used in the traditional plating process. It is important to find more sustainable alternatives to reduce the impact on the environment.

Reduced supply risk

The materials and technologies used in plating can be subject to supply risks. In addition, there may be a shortage of raw materials and price fluctuations. The search for alternative representations can establish a more stable supply chain and reduce risks.